The Quarter Master Protek Failsafe Electric Actuator features a rechargeable battery pack that is capable of 25 cycles under full load conditions, a built-in trickle charger, a low battery indicator, and an auxiliary limit switch that is calibrated with the fail position. The battery pack is installed inside of the actuator housing, so a separate enclosure to house the battery is not required.

When power is received from the primary power source, it is directed to the actuator motor and switches for normal cycling of the actuator. When the primary power source is interrupted, the battery pack is then connected to the motor and switches, and powers the actuator to a failsafe position. In this failsafe position, the auxiliary limit switch is tripped, and can be wired to an alarm. Once the primary power source is restored, the battery pack is disconnected and normal operation resumes.

Locations requiring both an electric actuator and a power-loss open/close backup.

Specifications

Sizes:

S92,A92, B92, C92

Voltage:

120 VAC, 1-phase, 50/60Hz

Conduit Entry:

one (1) 1/2″ FNPT

Cycle Time per 90º

15 seconds for S92 & A92*

32 seconds for B92 & C92*

Maximum Battery Current Charge:

200mA (13 Volts)

Torque:

400 in/lbs – 2000 in/lbs

Amp Draw:

0.2A – 4.0A depending on supply voltage

Max Ambient Termperature:

150ºF

Switches:

three (3) SPDT, 15 amp rated. two (2) for end of travel, one (1] auxiliary calibrated with fail position.

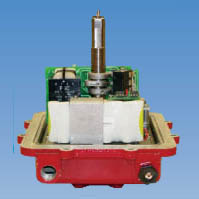

- Compact design: Rechargeable battery pack is installed inside of actuator housing

- Battery indicator: “Low battery charge” indicator light is installed in one of the conduit entries for visual status of battery charge

- Trickle charger: Standard unit is equipped with built-in, automatic trickle charger to maintain full charge to battery pack

- Battery power: Unit is capable of 25 continuous cycles, under full load, using only battery pack

- Remote-local switch: Located inside of housing facilitates start-up and maintenance

- Fail position: Calibrated for fail open or fail close

- Extended duty cycle: 50% – 75% duty cycle motor

- Gear train: Permanently lubricated, Rockwell hardened solid gearing

- Enclosure: Combination Type 4X, 7, & 9 enclosure for use in various environments

- Corrosion resistant enclosure: Thermally bonded baked powder coating with stainless steel trim

- ISO mounting configuration

- Conduit: 1/2″ FNPT conduit entry

- Position indication: Highly visible beacon position indicator for positive position of valve, even at a distance

- Declutchable manual override: Pull up on indicator knob, insert 5/8″ wrench onto flats and rotate in the appropriate direction (CCW for open/CW for close). Standard Features (continued)

- Models with handwheel override do not require a wrench. Simply push down on handwheel until engaged with cam and rotate

- Limit switches: Unit is standard with two end of travel limit switches, and one auxiliary limit switch that is calibrated with the fail position

- Corrosion resistant mounting: Mounting is with PPG or stainless steel bracket, stainless steel coupling, and stainless steel fasteners

- Output torque: Series 92 actuators have an output torque range from 400 in/lbs to 2000 in/lbs

- Voltages

- Heater and Thermostat

- Additional Limit Switch

- Feedback Potentiometer